You hit your target rate per mile. You booked what looked like premium freight. Yet, the weekly settlement is underwhelming. You’re left asking: “If my CPM was right, why was my week still wrong?”

The truth is, profitability isn’t murdered by low-rate loads. It’s assassinated by operational inefficiency. This is an execution failure, not a math failure. You can win every battle (individual loads) and still lose the war (your weekly profit).

This builds on our Cost Per Mile analysis where we calculated your true expenses. Knowing your number is the foundation. But now, let’s examine why that knowledge isn’t enough. While CPM tells you what each mile should earn, this is about why those miles often don’t connect profitably.

The Myth of the “Good Load”

A “good load” is often defined by one metric: a high rate per mile. This is a dangerous oversimplification. A load is only “good” in the context of the load before it and the load after it.

A $3.00/mile load that drops you in a dead freight zone is not a “good” load. It’s a trap.

A truly profitable load has three dimensions:

- Rate: The immediate revenue.

- Lane: Where it takes you (the future opportunity).

- Timing: When it picks up and delivers.

DAT Solutions data shows the national average deadhead rate often sits at 20-25%. For every four paid miles, you eat the cost of one empty mile. The American Transportation Research Institute (ATRI) notes that inefficient routing can slash a small fleet’s profit margin by 5-10% annually. That’s death by a thousand cuts.

The Three Silent Profit Killers

If individual loads are solid, the leak is in how they’re connected.

Killer 1: The Sequence Screw-Up

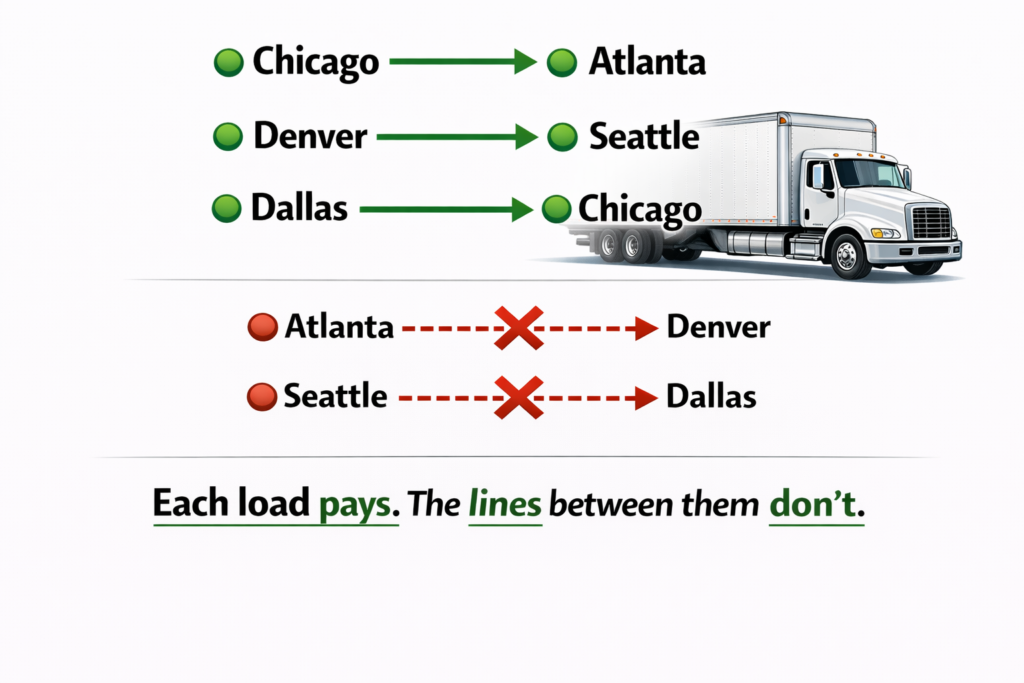

You have three great loads. But if you run them in the wrong geographic order, you’re hemorrhaging money.

- The Cost: Running Chicago → Atlanta, then Denver → Seattle, then Dallas → Chicago creates massive, unpaid deadhead between Atlanta, Denver, and Seattle.

Killer 2: The Timing Trap

A Friday afternoon delivery with no weekend pickup. A Monday pickup requiring a Sunday night deadhead. Timing is about minimizing non-revenue generating time.

- The Data: Studies show poor appointment synchronization can reduce a truck’s weekly utilization by 15%. You’re leaving money on the dock.

Killer 3: The Lane Decision Disaster

Chasing a premium rate into a weak outbound market. You get paid to go there, then accept a bottom-dollar load to get out, wiping out your gain.

- The Rule: You must think in round-trip revenue, not one-way rate. A $4.00/mile load into a $2.00/mile market is often worse than a $3.00/mile load into a balanced $2.80/mile market.

Key Stat: Fleets lose an estimated $8,000 – $15,000 per truck annually due to preventable sequencing and scheduling errors.

The Orchestration Mindset vs. The Load-Finding Mindset

The reactive Load-Finding Mindset asks: “What’s the best load available RIGHT NOW?” It’s transactional.

The proactive Orchestration Mindset asks: “What load available RIGHT NOW sets up the best possible load TOMORROW?” It’s strategic. You are the conductor of your business. Every move sets up the next.

Volatility is one of the clearest signals in determining when a dispatch service makes financial sense.

Practical Steps to Diagnose Your Dispatch Patterns

Most operators don’t realize where the money leaks until they slow down and look at their week as a whole. These aren’t complicated tools or software tricks. They’re simple habits that force you to step out of “load-by-load” thinking and see how your decisions actually connect.

The Weekly Map Audit

Once a week – ideally on Sunday – take ten minutes to map your previous route. Draw your loaded miles in green. Draw your empty miles in red.

What usually appears isn’t a clean loop, but a tangled web of zigzags and backtracking. That visual “spaghetti” is often the first honest look at where profit is being quietly burned – not on bad loads, but between them.

The “Next Load” Rule

Before you accept any load, pause and ask one uncomfortable question:

“Based on current market data, what realistic option do I have after this delivery?”

If you can’t name at least one solid follow-up lane, the rate on the current load probably isn’t telling the full story. This habit alone can prevent you from getting paid well on the way in – and punished on the way out.

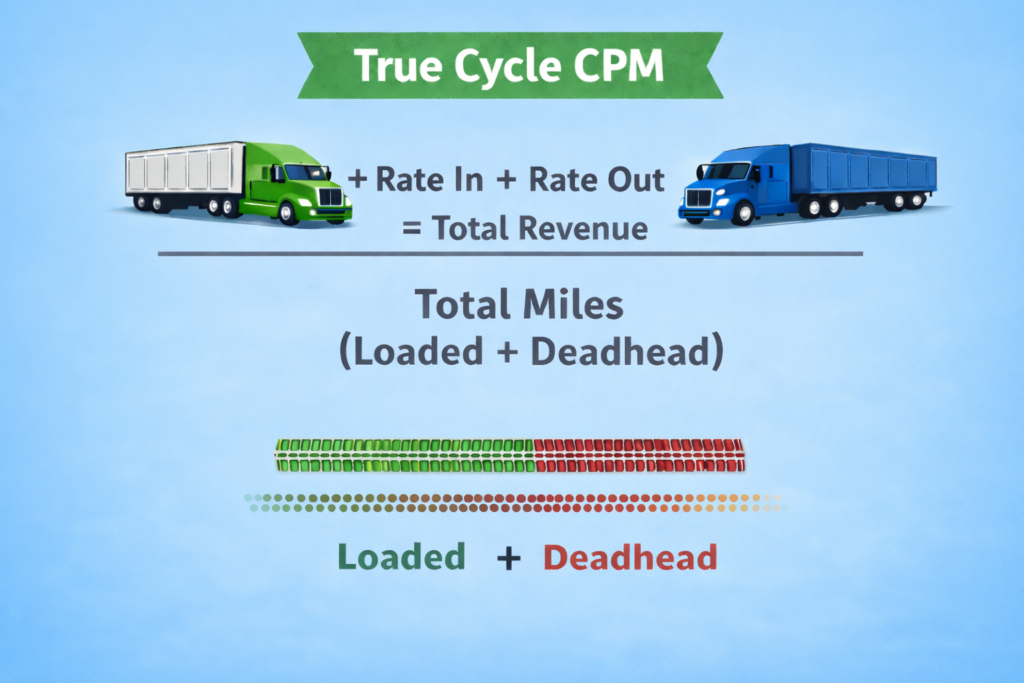

Calculate True Cycle CPM

When you’re deciding between loads, stop thinking in single legs and start thinking in cycles. For any potential move, run a quick reality check:

- Rate in plus the projected rate out of the destination

- Total revenue divided by total miles (loaded and estimated deadhead)

That number – not the headline rate – is your real metric. It tells you whether a load contributes to a profitable week or just looks good in isolation.

FAQ: Your Operational Questions Answered

Q1: I’m an owner-operator. I don’t have time to plan this intricately.

A: Dedicate 30 minutes each evening to plan the next 2-3 days. Use this time to analyze lanes and book in advance. It’s your highest-value work.

Q2: How much deadhead is acceptable?

A: Target under 15%. Consistently above 20% means your sequencing needs urgent attention.

Q3: Should I take a lower rate to get to a better market?

A: Often, yes. Use the True Cycle CPM. A $2.80/mile load to a strong market that sets up a $3.50/mile load back is better than a $3.20/mile load into a dead end.

Q4: What’s the single biggest dispatch mistake?

A: Chasing the highest rate without a plan for after delivery. It’s like grabbing cash without seeing if it leads into a dead-end alley.

Conclusion: From Calculation to Orchestration

Understanding your Cost Per Mile gave you the rulebook. But mastering the game requires thinking three moves ahead. Your truck is a revenue stream. The goal is to keep it flowing with as few interruptions (deadhead) as possible.

If this multi-dimensional puzzle feels like solving a Rubik’s Cube blindfolded, you’re not alone. This complexity is why many successful operators eventually delegate planning and load sequencing.

A great dispatch partner orchestrates weeks. They think in cycles and revenue streams, not transactions.

Your Next Step: Do the Weekly Map Audit of your last two weeks. If you see a tangled web of deadhead lines, the problem is clear. The solution is shifting from a load-finder to a revenue-stream orchestrator. Your truck – and your bank account – will thank you. This complexity is why many successful operators eventually delegate planning and load sequencing.