Truck fleet management is not just about maintaining vehicles — it is about keeping trucks loaded, productive, and economically viable week after week. For fleets that rely on daily freight movement, weak planning, idle time, or poor load coordination can quietly erode margins long before mechanical issues appear.

Whether you operate a small fleet or manage multiple trucks, effective fleet management ultimately comes down to utilization: how consistently trucks are loaded, how efficiently weeks are planned, and how much unpaid time accumulates between runs.

Defining Truck Fleet Management

At its core, truck fleet management in the freight industry encompasses the day-to-day oversight and operational activities of a collection of vehicles, whether it’s a small fleet or a larger one. In essence, fleet management involves coordinating and supervising all aspects of your vehicle fleet, regardless of its size. Whether your fleet comprises only a few vehicles or dozens of trucks, the term “fleet” pertains to the group of vehicles your company utilizes for the safe and timely transportation of goods. The fleet manager assumes ultimate responsibility for the maintenance and operation of these vehicles.

In practical terms, fleet management is also a revenue-control function. Beyond maintenance and compliance, it determines how often trucks are moving under paid loads, how much deadhead is absorbed, and whether weekly schedules are built proactively or reactively. Fleets with similar equipment often perform very differently based on how freight is planned and coordinated.

Fleets can consist of various vehicle types, including vans, pickup trucks, and cars. Common types of fleets include delivery, commercial, transport, and trucking fleets, but there are many other variations. Companies offering services like maintenance, laundry delivery, flower delivery, appliance transportation, or food and beverage delivery often operate fleets, even if they may not explicitly define themselves as such.

What is considered a fleet? To clarify, consider a local roofing company that recently added a sixth van to its lineup—this qualifies as a fleet. Similarly, a regional winery that operates eighteen trucks and several additional vehicles across the state also constitutes a fleet.

Given the substantial costs associated with fleet management, it’s no surprise that effective truck fleet management can lead to cost reductions of 17% to 22% compared to alternative outsourcing options. This substantial saving is achieved by efficiently managing various core functions, including asset management, fuel management, insurance, maintenance, route planning and optimization, safety and accident management, upfitting, vehicle purchase and licensing, and vehicle disposal.

You might wonder how much fleet owners can earn per truck or overall. On average, gross earnings per truck can range from $4,000 to $10,000, allowing owner-operators who oversee their fleet’s operations to take home around $2,000 to $5,000 per week. Keep in mind that these figures can vary due to factors such as mileage, driver efficiency, maintenance costs, seasonal fluctuations, and market conditions. In general, owning and managing a fleet can be a profitable endeavor.

The Significance of Truck Fleet Management

Proactive truck fleet management is essential for the long-term success of any fleet, whether it’s a small fleet management or a larger commercial vehicle fleet. Effective fleet management is centered on aligning drivers, vehicles, and the company’s overall mission to achieve critical business objectives.

The benefits of top-tier fleet management are significant and can impact various core aspects of the business, including delivery fleet management. It can stimulate growth, optimize operational efficiency, control costs, reduce accidents, and impact various core aspects of the business.

Fleet Utilization Matters More Than Fleet Size

Many fleets focus on growth – adding trucks, hiring drivers, expanding coverage – without first stabilizing utilization. In reality, a five-truck fleet with consistent reloads and controlled deadhead often outperforms a ten-truck fleet operating reactively.

Utilization gaps typically appear between loads: missed reload windows, thin outbound markets, and poor coordination between deliveries and next pickups. Over time, these gaps reduce paid-mile percentage and increase operating stress, even when freight demand remains strong.

Key Elements of Truck Fleet Management

Truck fleet management comprises multiple essential components, with some standing out as particularly critical, such as truck maintenance, compliance, and safety. The most successful truck fleets prioritize safety and regular vehicle maintenance, including commercial truck fleet maintenance. Scheduled maintenance is crucial to preventing unscheduled breakdowns and downtime.

Vehicle Management: This starts with vehicle acquisition. Efficient procurement strategies, including discounts and fleet programs from automakers, can save your fleet money. Fleet managers also oversee vehicle titles, licensing, and insurance to ensure all vehicles remain active and up-to-date.

Asset Management & Fuel Management: Proactive management of assets and monitoring fuel costs and consumption are central to cost savings. Analyzing whether investing in new vehicles outweighs maintenance and fuel savings is key.

Upfitting Requirements for Trucks: Some businesses require specialty vehicles for niche operations, necessitating upfitting. Fleet managers must plan for efficient and timely upfitting to avoid delays in vehicle deployment.

Truck Disposal and Resale: Disposing of vehicles at the end of their lifecycle is often overlooked. Fleet managers need to manage the sale process efficiently to maximize the value of each vehicle.

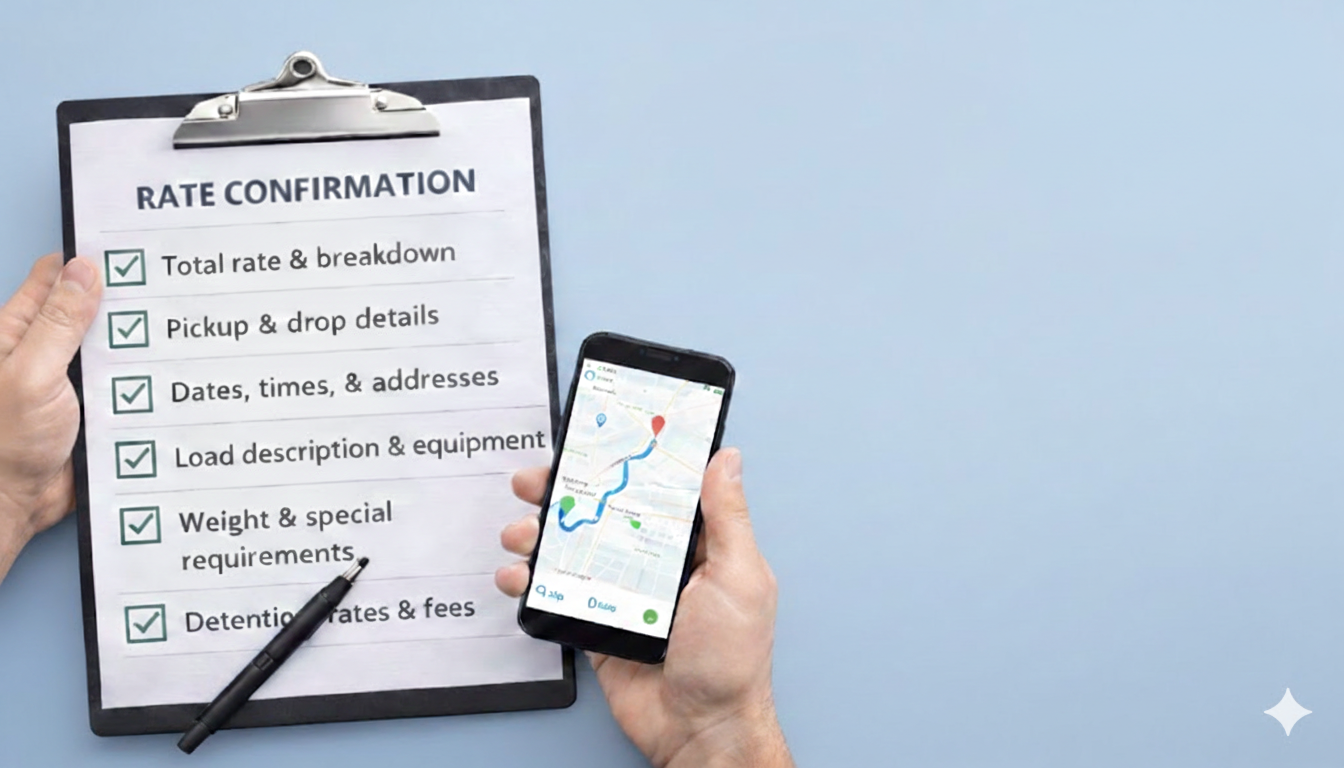

Efficient Route and Load Planning: Coordinating routes with delivery schedules and reload opportunities helps reduce unpaid miles and avoid reactive decision-making.

How to Manage a Fleet of Trucks

To effectively manage a fleet of trucks and take it to the next level, consider the following best practices, whether you have a small fleet or a larger commercial truck fleet companies:

- Hire a Full-Time Fleet Manager: Look for an organized, knowledgeable, and passionate fleet manager who can oversee the various elements of fleet management. You can start with a part-time manager before hiring a full-time one to manage costs.

- Partner with a Fleet Management Provider: Consider outsourcing some operational duties to fleet management companies, particularly for large fleets. This can save time and drive profitability.

- Develop Your Drivers: Invest in driver training and certifications to empower your drivers and enhance fleet performance. Establish safety standards and best practices to eliminate downtime.

- Establish Clear Communication: Maintain open lines of communication with drivers and stakeholders to ensure safe, effective, and timely operations.

- Leverage Technology: Utilize advanced technology systems and platforms to optimize fleet operations, increase efficiency, and drive long-term success.

How Dispatch Fits Into Fleet Management

For small fleets and owner-led operations, fleet management often breaks down at the planning stage — not because of equipment issues, but due to time constraints. Load sourcing, broker communication, reload timing, and paperwork coordination all compete with driving and management responsibilities.

Dispatch support functions as an extension of fleet management by focusing on weekly load flow rather than individual shipments. By coordinating loads ahead of delivery, managing broker communication, and reducing unpaid gaps between runs, dispatch helps fleets stabilize utilization without adding internal overhead.