Empty miles are rarely just a routing issue – they’re usually the result of earlier planning decisions. Where a truck delivers, how the next load is sequenced, and whether lanes are repeatable often determine how much deadhead a carrier absorbs over time.

Reducing empty miles through route planning, efficient logistics operations, and cooperating with freight dispatchers can help trucking businesses enhance operational efficiency and increase their revenue. Whether managing less-than-truckload shipments or planning return trips, optimizing delivery routes ensures each truck travels with a purpose, benefiting the entire supply chain.

What is Empty Miles?

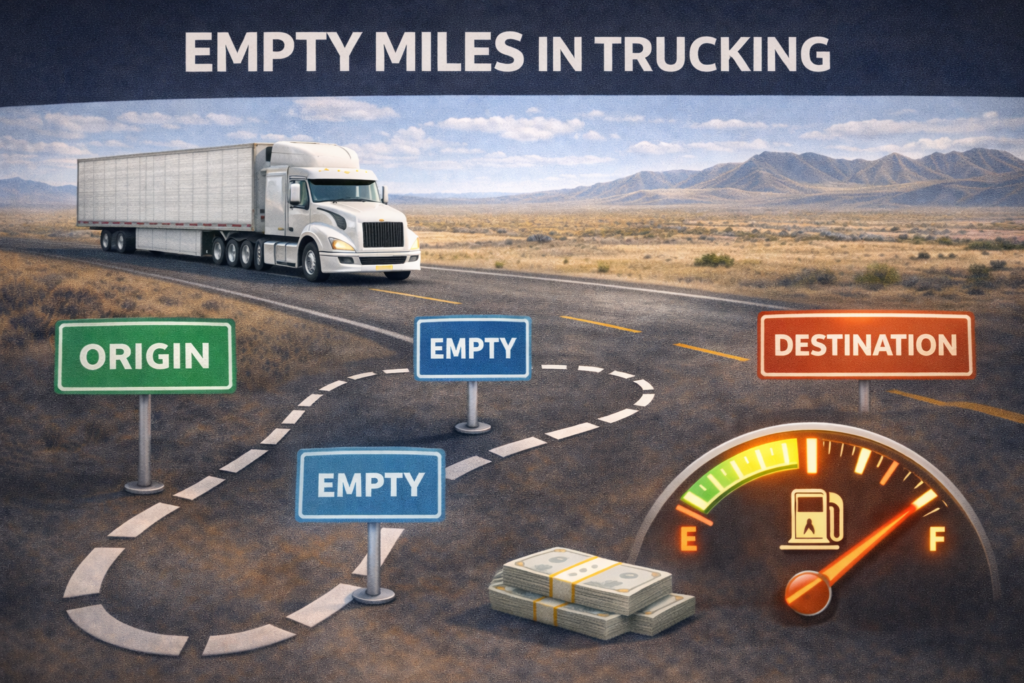

Empty miles concept refers to the miles that trucks drive without a cargo. They are also known as deadhead miles or unloaded miles. In the freight transportation industry, many logistics companies and owner-operators face the challenges of empty trucks on the road. Every mile driven without cargo reduces the revenue, hurting the freight network.

The main scenario when empty miles can occur is the return leg of a shipping process. After a delivery, trucks may return to their base or the next location without a load.

Fewer empty miles mean that more trucks are busy transporting cargo. This helps improve operational efficiency and enhance environmental sustainability. In addition, fewer empty miles reduce fuel consumption, leading to lower expenses.

Thus, empty miles show where inefficient routing occurs, which can be fixed with better planning and advanced algorithms.

Financial Impact of Empty Miles on Trucking Operations

Empty miles can significantly cost logistics operations. Understanding the true cost of deadhead requires looking beyond fuel and considering how positioning affects the rest of the week.

When trucks drive without freight, the miles they travel are non-revenue and add to operational costs. This means that even though truck drivers are paid, the truck is not earning money because it is not transporting cargo.

In addition, empty miles can result in increased fuel consumption and higher wear and tire on delivery vehicles. For companies that try to reduce their carbon footprint, empty miles are an additional issue, as more fuel consumption means more carbon emissions.

Logistics companies and other businesses can use advanced route optimization algorithms to identify opportunities to reduce empty miles. This can result in cost savings and improved profitability.

Overall, reducing empty miles saves money and helps create a more sustainable and efficient freight network for the logistics industry.

Strategies to Reduce Empty Miles in Trucking

Nowadays, every mile matters for the transportation industry. Thus, reducing deadhead miles is a top priority for most logistics companies and independent truck drivers.

Reliable strategies on how to handle empty miles can benefit the supply chain and the entire US logistics industry. Four main strategies include route planning, the use of reverse logistics, the use of load boards, and the implementation of multi-stop routing.

Route Optimization and Planning

Route optimization is the backbone of reading empty miles. With the use of advanced technologies and tools, trucking businesses can optimize their routes. This requires taking into account weather conditions, traffic, and other factors. This process ensures that delivery vehicles follow the best possible paths, avoiding inefficient routing that leads to empty vehicles on the road.

Planning delivery routes carefully can turn these miles into revenue-generating activities rather than just non-revenue empty miles. In many cases, even the total miles a truck travels can be planned to reduce empty miles and lower shipping expenses.

With reduced fuel consumption and costs, companies see savings that benefit the freight network. This approach has proven its positive impact by making the entire system more efficient.

Leveraging Backhaul and Reverse Logistics

Another strategy to combat empty miles is to plan for the return journey through backhaul and reverse logistics. Instead of unloaded trucks traveling back to the distribution center or their base without cargo, companies can find loads for the return leg of the trip. This means trucks are used for transporting cargo on both outbound and return trips.

By leveraging reverse logistics, companies can fill their vehicles with shipments from several customers. When a truck picks up a load on its way back, it transforms unnecessary empty miles into revenue-generating tasks. This approach tackles operational costs linked with deadhead miles.

Businesses can use tools like load boards to find a load for a reverse journey or consider cooperating with freight dispatchers to find a load. As a result, there are fewer trucks traveling with no load.

Using Freight Matching

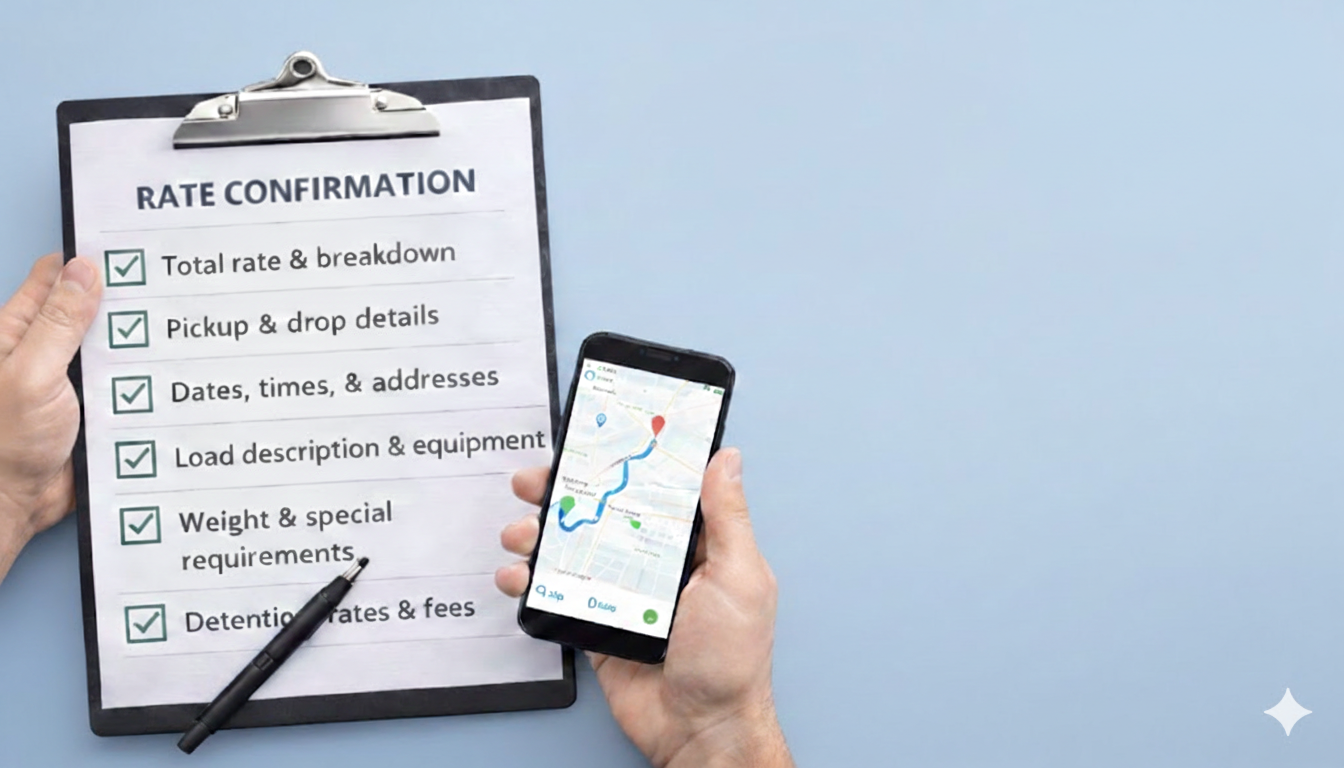

Modern load boards and freight matching tools transformed how logistics operations manage trucking miles. These platforms connect truckers with available cargo that fits their route and preferences. With an easy load search, drivers can quickly find shipments that match their schedules.

When freight matching systems are in place, every mile is more likely to provide profit. This ensures that delivery vehicles are consistently busy transporting cargo rather than running empty miles. Whether you are part of a large logistics company or operating as an independent driver, these tools help optimize shipping routes and ensure that miles are not wasted.

Implementing Multi-Stop Routing

Another effective method is multi-stop routing, which allows the delivery vehicle to make several stops during its journey. This helps fill the truck and ensures every mile is productive.

For instance, a truck can start at a distribution center, deliver to one customer, and pick up a load from another before heading to the next destination. This is especially effective for less-than-truckload shipments, where cargo from multiple customers is combined into one truck.

By planning stops along the way, logistics operations can plan shipping routes so that every leg of the trip contributes to the revenue.

With advanced tools and careful planning, routes can be designed to require fewer truckshe same number of stops.

This strategy’s simplicity makes it accessible for logistics companies of all sizes. The trucking sector has embraced it to significantly reduce empty miles.

Where Coordination Changes the Outcome

Reducing empty miles consistently requires coordination across pickups, deliveries, and reload planning. That coordination can be handled internally, but many small carriers lack the time to monitor lane balance, reload probability, and market shifts while also driving.

Some operators address this by adding structured planning support focused on sequencing freight and keeping trucks positioned in repeatable lanes rather than reacting load by load.

Conclusion

Minimizing empty trips is essential for improving the freight network, increasing cost savings, and reducing carbon dioxide emissions. By using advanced algorithms for route planning and load-matching technology, companies can identify opportunities to fill empty return trips.

Partnering with a professional dispatch service can help logistics companies and independent contractors optimize routes, secure better loads, and increase profitability.

At Logity Dispatch, we specialize in helping trucking companies and owner-operators maximize their earnings by reducing empty miles and improving overall efficiency. Our team of expert dispatchers assists with load matching, route optimization, and regulatory compliance, ensuring fewer vehicles traveling without cargo.

Minimizing empty miles is less about finding one extra load and more about building repeatable lanes, predictable reloads, and decisions that account for where the truck will be tomorrow – not just today.