Choosing between a dry van and a reefer is not just a trailer decision – it’s a business model decision. For carriers and owner-operators, the difference affects load availability, waiting time, reload options, and how predictable a week actually is.

While dry vans and reefers are two of the most common trailer types in trucking, they behave very differently in real operations. Rates, dock time, freight density, and seasonal volatility all play a role in how each trailer performs once the wheels start turning. A reefer may offer higher per-mile rates, while a dry van often delivers steadier reloads and fewer operational delays.

This guide breaks down the practical differences between reefer and dry van operations — not just what each trailer is used for, but how they impact weekly income, scheduling risk, and long-term efficiency. We’ll compare use cases, pricing realities, and operational tradeoffs, including when a reefer can realistically be used as a dry van and when that flexibility actually creates problems instead of profit.

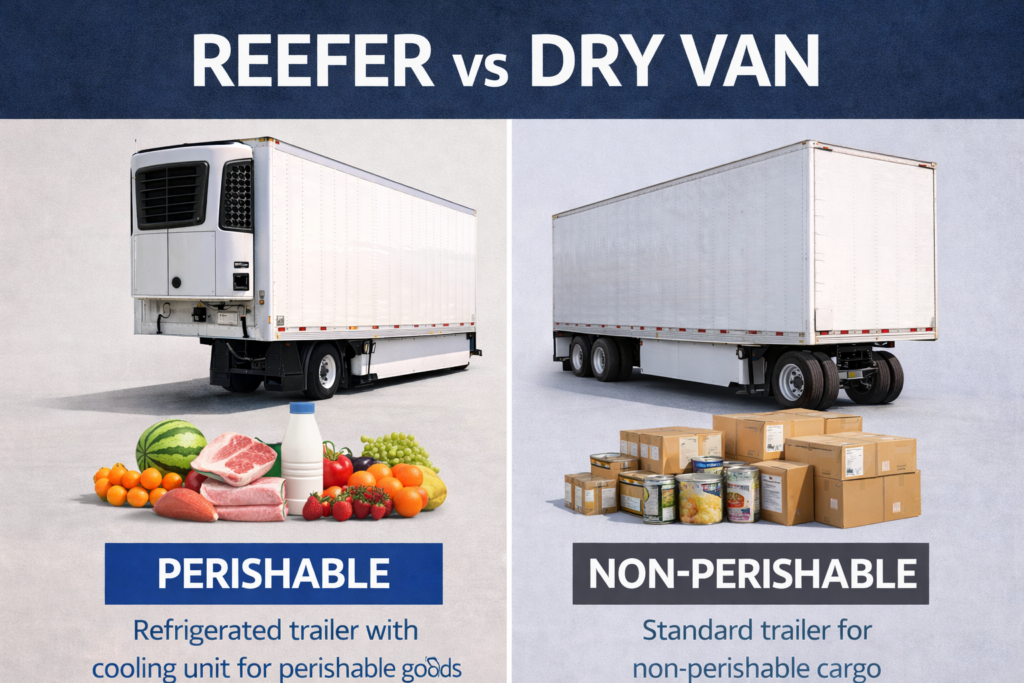

What are Dry Vans?

Dry vans, renowned for their versatility and ample capacity, rank as the most prevalent trailer type within the trucking industry. Typically, carriers employ these unrefrigerated trailers to transport dry, non-perishable goods that don’t demand controlled temperature conditions.

These goods encompass a wide range, including kitchen appliances, non-perishable food items, furniture, electronics, and clothing. If you’re curious about reefer trailer dimensions, a typical reefer trailer is around 13.5 feet in height and 8.5 feet in width, much like dry vans, but their length can vary, falling within the range of 48 to 53 feet. Some dry van trailers are outfitted with loading ramps or roll-up doors, while others feature aerodynamic skirts.

Advantages of Using a Dry Van

Dry vans offer numerous advantages to carriers, making them a preferred choice for various transportation needs. These benefits include:

1. Versatility for Various Cargo: Dry vans are versatile and capable of transporting a wide range of goods, whether it’s designer clothing, building materials, cleaning products, electronics, kitchenware, or other non-perishable items. This flexibility makes them suitable for diverse cargo types.

2. Convenience and Time Savings: Dry vans are known for their convenience, allowing carriers to efficiently use the drop and hook load method. This means you can drop off a loaded trailer, immediately pick up a new one, and get back on the road without waiting for unloading. This time-saving feature helps maximize your profitability.

3. Enhanced Security: Dry van trailers provide a high level of security. They are fully enclosed and easy to lock, making it challenging for anyone to steal your cargo. Additionally, the enclosed design protects your cargo from theft, damage, and external elements like rain, snow, hail, ensuring safe transportation regardless of the weather conditions.

Cons of Using a Dry Van

One of the primary disadvantages of dry vans is their wooden flooring. Wood is susceptible to damage from condensation and moisture, which may result in more frequent maintenance and repairs compared to other types of trailers. Moisture buildup can be caused by various factors, including the nature of the cargo itself or loading and unloading during adverse weather conditions.

Despite these drawbacks, dry vans remain a popular and viable choice for many carriers, especially for non-perishable and versatile cargo

What is a reefer trailer used for?

Reefers, or refrigerated trailers, are designed to transport perishable goods and items requiring controlled temperature conditions during transit, defining their reefer meaning in trucking. This key distinction sets reefers apart from dry vans, making them well-suited for a wide range of cargo, including frozen foods, pharmaceuticals, and chemicals. While reefers excel at temperature-sensitive goods, they are also versatile enough to transport dry loads, addressing concerns about the best reefer trailer to buy. They provide security from theft and adverse weather, with constant demand for temperature-sensitive goods often resulting in higher rates for reefer services. Reefer trailers with their insulation and metal floors, offer a secure and climate-controlled environment for cargo.

When considering how much weight can a reefer trailer carry, it’s important to note that reefer units add weight, reducing your load capacity by around 500 to 1,000 pounds, resulting in an average load capacity of 42,500 pounds. This reduction may lead to declining certain loads due to load capacity constraints, which is a key consideration for carriers.

Advantages of Using a Reefer:

- Cargo Protection: Reefers provide secure and weather-resistant cargo storage, offering excellent protection against theft and adverse weather conditions.

- Consistent Demand: The constant need for transporting perishable goods ensures a high demand for reefer services. This demand often results in higher rates, making it a lucrative business opportunity.

- Remarkable Versatility: Reefers can transport both temperature-sensitive and dry goods, simplifying back-hauling and providing more load options for increased profitability.

Disadvantages of Using a Reefer:

- Increased Responsibility: Operating a reefer entails additional responsibilities, including meticulous monitoring and maintenance of cooling equipment and regular trailer cleaning to meet strict cleanliness standards.

- Longer Preparation Time: Pre-cooling requirements lead to longer preparation times compared to other trailer types.

- Cargo Restrictions: Reefers are not suitable for heavy or oversized loads and can be noisy due to temperature control.

- Extended Loading/Unloading Times: Loading/unloading at docks can take longer, as most reefers aren’t suitable for quick drop-and-hook procedures.

- Higher Costs: Reefers are generally more expensive due to their equipment and fuel consumption. This should be considered when comparing reefer vs dry van rates.

Which one is better?

So, in the reefer truck vs dry van comparison, the choice depends on various factors, including the type of cargo you intend to transport and whether you require climate control trailer for your cargo. While both trailer types offer secure and weather-resistant cargo storage, reefers excel at temperature-sensitive goods, while dry vans are versatile for non-temperature-sensitive cargo. Despite the higher initial cost of reefers, the potential for higher rates due to lower competition makes them a profitable choice for many carriers. Your decision should align with your cargo requirements and business strategy, ensuring that you find the optimal solution for your needs.

From a weekly income perspective, the difference between reefer and dry van is less about rates and more about flow.

- Reload availability: Dry vans generally reload faster and in more locations, while reefers often depend on fewer, time-sensitive shippers.

- Waiting risk: Reefer loads are more prone to dock delays due to inspections, temperature checks, and appointment rigidity.

- Deadhead exposure: Reefer freight can pay more per mile, but poor reload geography often increases unpaid repositioning.

- Schedule predictability: Dry van operations tend to offer steadier weekly planning, while reefer income is more volatile but can spike during seasonal demand.

For many owner-operators, the “better” trailer is the one that produces consistent weeks, not just higher headline rates.

Choosing Between Reefer and Dry Van Is Ultimately a Planning Decision

Reefer and dry van operations require different approaches to reload timing, broker communication, and weekly positioning. The trailer itself doesn’t determine profitability – how the week is planned around it does.

Dispatch support is often used by owner-operators running either trailer type to reduce deadhead, manage appointment risk, and keep weeks structured instead of reactive.