Table of Content

- The Week, Not the Load, Is the Real Profit Unit

- Detention and Waiting Time: The First Silent Profit Leak

- Reload Geography: Why Where You End Matters More Than Rate

- Appointment Compression and Why Tight Schedules Break Weeks

- Why Load Boards Don’t Show the Full Picture of Weekly Performance

- Why Weekly Planning Outperforms Load-by-Load Optimization

- Why Skilled Drivers Still Struggle With Reload Timing

- Where Dispatch Planning Changes the Equation

- Predictability Beats Peak Rates

- Conclusion

In trucking, inconsistent income rarely comes from bad freight. More often, it comes from weak connections between otherwise decent loads. Owner-operators regularly describe weeks where rates looked fine, miles were driven, and compliance boxes were checked – yet the week still underperformed.

The difference between a strong week and a frustrating one usually isn’t the rate on a single load. It’s reload timing.

In trucking, reload timing refers to how effectively a delivery connects to the next load within the same operating week – and it remains one of the strongest predictors of consistent income.

The Week, Not the Load, Is the Real Profit Unit

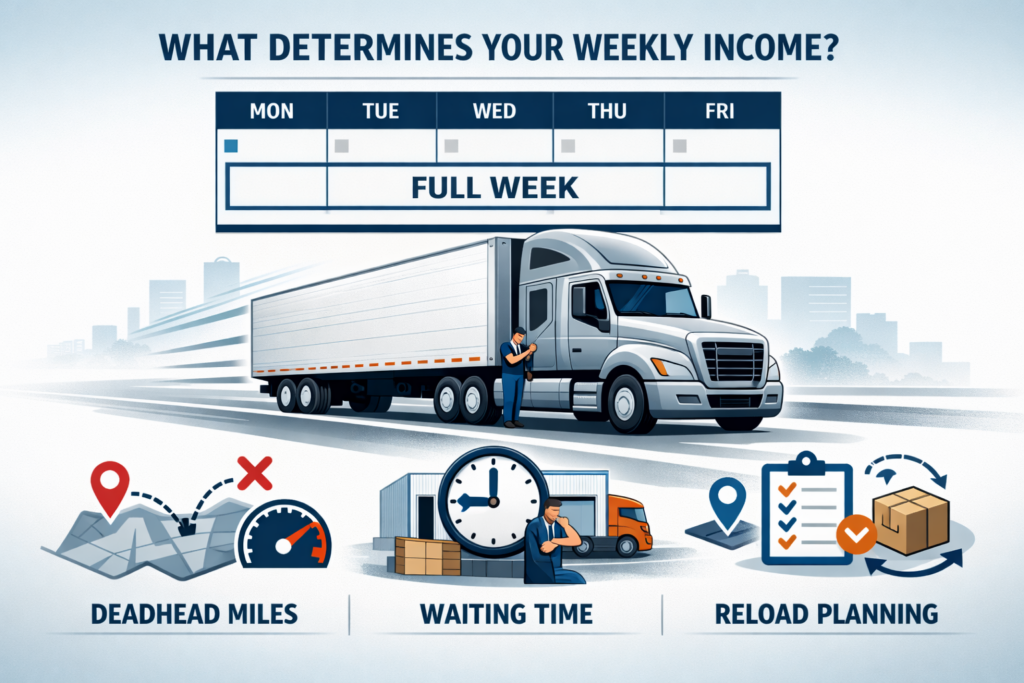

Industry benchmarks reinforce a simple reality: profit is determined weekly, not load by load.

ATRI’s Operational Costs of Trucking shows that non-revenue time – detention, deadhead, and underutilized driving hours – now accounts for over 20% of effective cost per mile for owner-operators. Fuel prices fluctuate and rates move with the market, but lost time compounds quietly and relentlessly.

A typical target week of 2,800 paid miles that closes at 2,350 miles doesn’t fail because freight disappeared. It fails because time was lost between loads – waiting at docks, repositioning for reloads, or sitting in weak outbound markets. At an average $2.20 per mile, that gap represents nearly $1,000 in lost gross revenue without a single “bad” load on the books.

Detention and Waiting Time: The First Silent Profit Leak

FMCSA data and shipper behavior both confirm that detention beyond two hours remains widespread, despite contractual language intended to limit it. For a solo operator, three hours of waiting repeated several times per week quickly adds up.

Nine lost hours over a week equates to roughly 450 miles that could have been driven. Detention pay, when it exists at all, rarely compensates for the downstream effects: missed reload windows, forced overnight delays, and reduced scheduling flexibility.

Waiting does not show up on rate confirmations, but it consistently determines whether a week holds together.

Reload Geography: Why Where You End Matters More Than Rate

Load boards excel at showing rates. They do not reveal reload depth.

Industry lane analysis consistently shows that freight-dense markets support same-day or next-day reloads, while thin outbound regions routinely add 150-300 unpaid repositioning miles per week. A $3.00-per-mile load into a weak market often underperforms a $2.40-per-mile load into a strong one once deadhead and waiting are accounted for.

ATRI estimates average deadhead for owner-operators in the 15-20% range. Poorly planned weeks often exceed 25%, where fuel, maintenance, and fixed costs continue to accrue while revenue miles shrink. The math does not forgive geography.

Appointment Compression and Why Tight Schedules Break Weeks

Tightly stacked appointments often look efficient on paper. In practice, they introduce fragility.

A common pattern looks like this: a Thursday delivery runs three hours late, the Friday reload slips into the afternoon, and the only option left pushes the truck into a weak outbound lane. The rate looks fine on paper, but the week closes short – not because of bad freight, but because timing collapsed.

Once timing slips, recovery options narrow quickly. Reloads weaken, negotiation leverage erodes, and the rest of the week becomes reactive.

Why Load Boards Don’t Show the Full Picture of Weekly Performance

Load boards operate on snapshots of supply and demand. They answer what is available now, not how today’s decision affects tomorrow’s options.

They do not account for lane continuity, appointment flow, or reload reliability. As a result, drivers booking one load at a time often optimize short-term rate at the expense of weekly utilization. Over time, this produces inconsistent results even when individual loads appear sound.

This is why many experienced operators accept slightly lower headline rates to protect flow – a pattern also explored in How Dispatch Support Helps Truck Drivers Stay Loaded.

Why Weekly Planning Outperforms Load-by-Load Optimization

Drivers who consistently outperform industry averages think in weeks, not loads.

They gravitate toward repeat lanes, known shipper behavior, and markets with predictable reload patterns. Deadhead is treated as a positioning tool rather than an emergency response. This approach aligns with ATRI’s findings that time efficiency – not just rate per mile – drives profitability.

Small improvements in utilization compound quickly. Isolated rate spikes rarely do.

For a deeper breakdown of how deadhead quietly erodes weekly performance, see The Guide to Managing Empty Miles in Trucking.

Why Skilled Drivers Still Struggle With Reload Timing

Most owner-operators simultaneously manage driving, sales, scheduling, compliance, paperwork, and negotiation. Under that workload, planning often becomes reactive by necessity.

Reloads are searched after delivery instead of before. Lane strategy shifts mid-week. Rate discussions happen under time pressure rather than leverage. This is not a failure of discipline or experience – it is a capacity constraint.

Where Dispatch Planning Changes the Equation

Dispatch does not create freight. It reduces waste.

At its best, dispatch planning focuses on connecting loads into a viable week, identifying reloads before delivery, steering toward freight-dense lanes, managing broker communication early, and negotiating rates without sacrificing timing.

Reducing deadhead from 25% to 18% on a 2,800-mile target week restores nearly 200 paid miles. That is a structural gain, not a market fluke. Reload timing often determines whether a dispatch service is worth the cost.

Predictability Beats Peak Rates

In volatile markets, operators who protect utilization and timing consistently outperform those chasing isolated high-paying loads. Predictable weeks generate steadier income, lower stress, and better decision-making.

Perfect loads are rare. Controlled weeks are repeatable.

Conclusion

Good loads do not guarantee good weeks and the data makes that clear.

Weekly performance is shaped by paid-mile percentage, reload positioning, waiting time, and planning discipline. Operators who evaluate loads in isolation often lose profit between them. Those who plan the entire week – whether independently or with support – reduce waste and stabilize outcomes.

In trucking, the real competitive advantage is not finding the best load.

It is building weeks that hold together.

Consistent reloads are planned and not searched last minute.

Dispatch planning exists to protect the entire week, not just the next rate.